Responsibility to the Planet

Our products and the process leading up to their creation must be as planet-friendly as possible. We see this as our share of responsibility for the future of the environment in which we have to live.

Paper-based materials are the basis of packaging. But also adhesives, foams and many others. We choose those that are proven to be environmentally friendly and leave the lowest possible carbon footprint.

A general problem with packaging is its short life cycle. Once it has served its purpose, it is usually disposed of. We design and manufacture high added value products for our customers that have the potential to find a second life. A beautiful and well thought out box can further serve as an interior accessory or a storage component for the office.

We prefer local suppliers because the shorter the distance the production process has to travel, the lower the negative impact on the environment. For example, the Lessebo paper mill uses pulp from the surrounding forests, water from the river behind the mill and wind power for production. Their paper is then used to produce, for example, a large series of complicated products in the Czech Republic in cooperation with partners in our vicinity. This will give our clients a more planet-friendly alternative to traditional imports from the Far East.

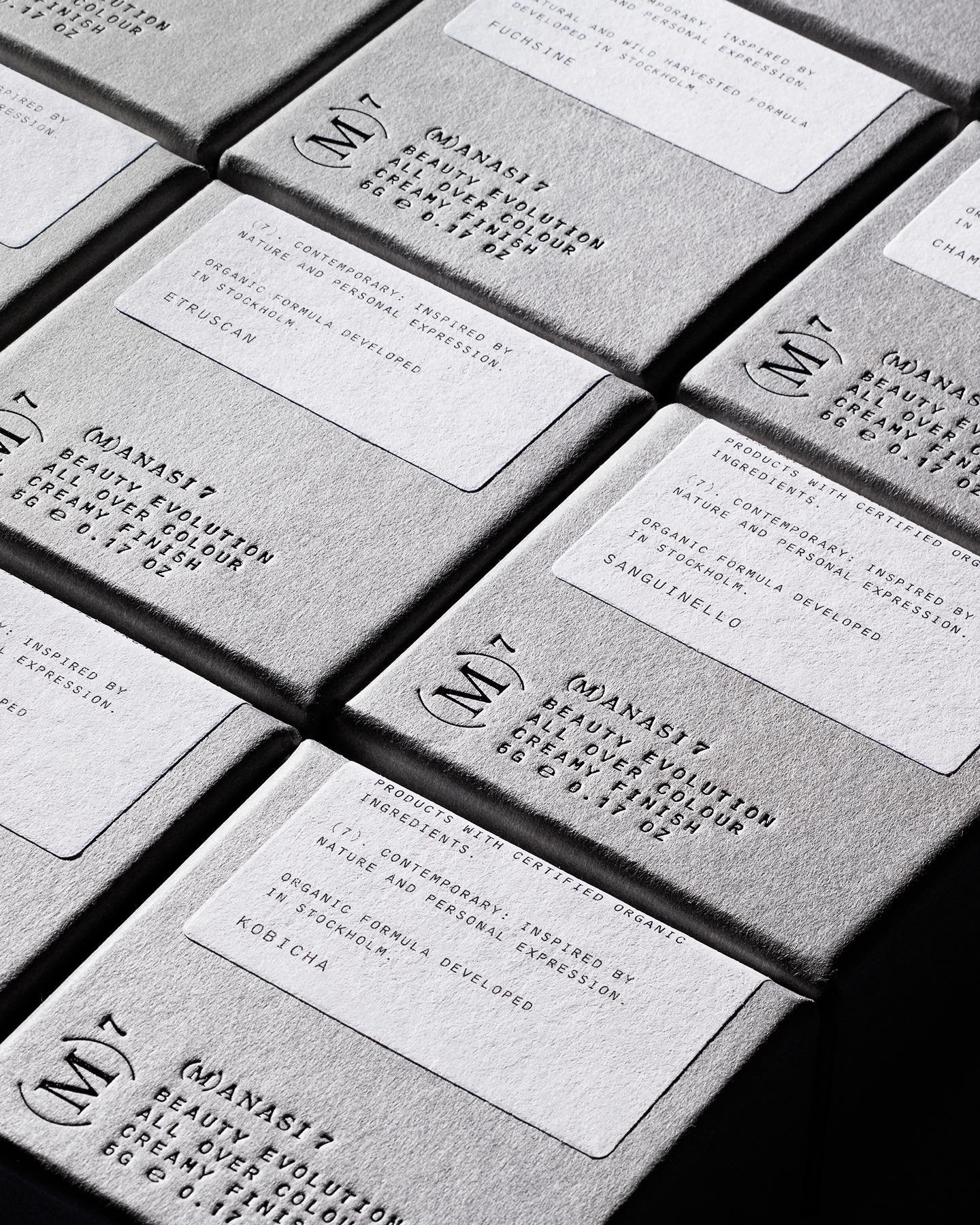

Manasi7 - August 25, 2022 - Instagram

" Extended life

All of our packagings are made in a slow pace and an environmentally friendly way from the beginning to the end to minimize waste. The reusable and recyclable handcrafted custom designed paper boxes are made of high quality paper that can have extended life. The paper material that is used is derived from wood that grows in sustainably managed forests. Reuse is a good way to prevent waste from entering the waste stream. Save your paper box, take good care of it and fill it with jewellery, supplements or anything else of preference. The production cycle emphasizes on minimizing the environmental footprint.

Read more at www.manasi7.com "

Sustainable Production Glossary

-

1% for the Planet is a global movement inspiring businesses and individuals to support green solutions through annual memberships and daily actions. Your donation is 1% of your annual turnover or salary.

-

Lightweight, soft and rust-resistant metal that is commonly used in packaging. Applications include foil or shaped items such as cans and trays. Easily recyclable.

-

Asthma Allergy Nordic is a collaboration between asthma and allergy organisations in Norway, Sweden and Denmark. This label makes it easier for customers to find environmentally friendly products.

-

Bisphenol A - a thermoset plastic known for its use as a coating inside food cans. Its use is controversial due to questionable health effects.

-

A form of pulp that is specially made from the waste material of sugar cane production. It can be pressed into paper or moulded for use in packaging. It may be a cheaper option as it is considered waste.

-

Paper made from bamboo shoots (grass) instead of traditional wood fibre.

-

Plastics made from renewable, non-fossil sources such as sugar cane or corn. Although their origins are renewable, these plastics share similar properties to their fossil fuel cousins and can be just as problematic pollutants for the planet. They represent a step in the right direction, but still require careful life cycle management.

-

Plastics that can decompose into water or CO2 through industrial processing. They are appreciated for having a positive impact on the planet, but it is important to know that this depends on cities having the necessary infrastructure. No plastic can yet decompose naturally or without human help.

-

A soft wood commonly used to make disposable wooden cutlery and plates. It is also used to make pulp.

-

The letters "CE" appear on many products traded in the expanded single market in the European Economic Area (EEA). They indicate that products sold in the EEA have been assessed as meeting high safety, health and environmental protection requirements.

-

Computer Numerical Control Machining - a two-axis machine that uses rotary cutting tools or special knives to cut sheets of material. CNC machines can be calibrated or custom built to suit a variety of materials, from paper sheets to marble slabs.

-

The most common black dye used in plastics. NIR (near infrared) technology cannot read soot because it does not reflect light, making it difficult to sort in recycling facilities.

-

A new kind of business that balances purpose and profit. Certified companies are required to consider the impact of their decisions on their workers, customers, suppliers, community and the environment.

-

A type of foam that has a surface structure similar to the air pockets in bread which prevents the passage of moisture and gases.

-

Paper can be coated with various natural or chemical materials to achieve specific surface finishes or structural qualities (weight, stiffness, gloss, smoothness).

-

A process in papermaking that produces coarser, more textured sheets. The cold pressing process shapes the pulp into sheets without heat, allowing its fibres to fuse together while better retaining their individual shape and volume. Cold-pressed paper generally has a better texture.

-

Made by mixing two or more materials to create one optimized material. The aim is to improve properties such as lightness, stiffness and/or strength. Composites can be difficult to recycle - examples include fibreglass, particleboard and reinforced concrete.

-

The bark/tissue that grows on a particular type of oak tree called cork oak. This is a renewable resource that can be harvested every ten years (hence it is harvested on a rotating basis to allow for continuous harvesting of the resource). Examples include bottle stoppers and containers or customized trays.

-

Foam made from corn starch. It is a relatively new alternative to polystyrene (EPS) that performs comparably in crash tests and as thermal insulation. It degrades in water and reportedly has no negative impact on the marine environment. However, it does require a protective layer (usually plastic) to prevent premature decomposition when exposed to moisture - perhaps worthwhile when considering the overall reduction of plastics.

-

Lines that are pressed into the material without cutting it. This compression creates a weak point that is prone to bending, making it easier to accurately fold the material. Also known as creasing.

-

Recessed detail on the surface of cardboard or paper. A trick to remember - D for down.

-

A manufacturing process that uses a mould (called a die) to stamp shapes out of sheet materials (paper, cardboard, thin metal or plastic). Most cardboard boxes are made by die-cutting in some way. A simple example would be a standard office punch.

-

Expanded polystyrene - a cheap, lightweight and robust filling material commonly known as polystyrene. Although it resists impact and holds its shape well, it is not recyclable. Relevant applications today are usually limited to packaging for heavy and fragile products.

-

The EU Ecolabel is a label of environmental excellence awarded to products and services that meet high environmental standards throughout their life cycle: from extraction of raw materials to production, distribution and disposal.

-

Raised detail on the surface of a card or paper. With or without foil application.

-

E-mark can be found on some packaged products (food, beverages, cosmetics, cleaning) in Europe. Its use means that the finished packaging complies with the relevant European laws.

-

The FSC (Forest Stewardship Council) label provides information on the origin of the materials used to produce the finished and labelled product.

-

A label stating that all materials used in the products come from forests that have been audited by an independent third party to confirm that they are managed in accordance with strict FSC social and environmental standards.

-

A label stating that the products are made from a mixture of materials from FSC certified forests, recycled materials and/or FSC controlled wood.

-

A label stating that the products have been verified as being made from 100% recycled content (either post-consumer or pre-consumer recycled materials).

-

Fairtrade is changing the way trade works through better prices, decent working conditions and fairer treatment for farmers and workers in developing countries.

-

The material commonly known as cardboard-wool is a group of fiber-based boards that have a layered structure and a wavy center. This corrugation gives the material strength and can vary in both thickness and density. Wool is available in many forms and standard thicknesses can vary depending on the manufacturer. The exact thickness must be considered before manufacturing.

-

Type N - thickness 0,4-0,8 mm

Type F - thickness 0,9-1,2 mm

Type E - thickness 1,2-2,0 mm

Type B - thickness 2,5-3,0 mm

Type C - thickness 3,5-4,0 mm

Type BE - thickness 4,0-5,0 mm (double corrugated centre)

Type BC - thickness 6,0-7,0 mm (double corrugated centre)

Type AB - thickness 8,0-9,0 mm (double corrugated centre)

-

An international symbol indicating that the material used in a product is considered safe for contact with food. Shown as a wine glass and fork.

-

Grams per Square Meter - 100 gsm paper is often lighter and thinner than 400 gsm. GSM can also correspond to stiffness and strength, but this is not always the case.

-

Commonly used in packaging as jars and bottles - glass is generally considered a heavy material when comparing strength to weight ratios. It has great value in recycling chains and is considered a greener solution compared to plastics.

-

The adhesive is commonly used for binding materials or adding labels to packaging. There are many products, all with varying quality (holding strength) and toxicity levels. In general, it is best practice for adhesives to be water soluble at low temperatures (below 60°C) to facilitate removal during recycling.

-

Green Dot is a non-profit company that provides funding for product recycling around the world. The symbol does not mean that the product itself is recyclable, but that the company that made the product has paid the Green Dot recycling fee.

-

High-density polyethylene - a heavy-duty variant of PE (polyethylene) that has a higher density chemical composition, making it more suitable for applications requiring material strength - such as deodorant containers (with screw caps) and water pipes (with high pressure) . It can be translucent but not clear.

-

Manufacturing that relies on manual labour to assemble products or packaging. This is much more common than people usually assume.

-

A process in papermaking that produces highly smooth sheets. The hot pressing process has a similar effect to household irons, forcing the pulp fibres to join together evenly to form a sheet.

-

A set of international standards issued by ISO (International Organization for Standardization) that help organizations ensure that they meet the needs of customers and other stakeholders within the legal and regulatory requirements related to a product or service.

-

Standard used in most of the world except North and Latin America. All paper sizes have the same aspect ratio. This includes paper such as A4 (210 x 297 mm).

-

Low density polyethylene. A lightweight variant of PE (polyethylene) that has a lower density chemistry, making it more suitable for applications requiring ductile material - such as plastic bags or snap caps. It has good tear resistance. It can be translucent but not clear.

-

Foam made of LDPE (low density polyethylene). It is commonly used as a padding for technical and lighting products because it can withstand multiple impacts and hold its shape. LDPE foam is usually supplied in sheets that are cut and cut into products to form bumpers. Unlike EPS (white polystyrene), it is recyclable in most countries.

-

Made by layering two or more materials to create one optimized material. For example, bonding plastic film to cardboard provides the rigidity of cardboard with the water resistance of plastic. Laminates can be difficult to recycle - examples include coated paper or engineered flooring.

-

A manufacturing process that uses a mould (called a die) to stamp shapes out of sheet materials (paper, cardboard, thin metal or plastic). Most cardboard boxes are made by some form of die-cutting. A lightweight manual example would be a standard office punch.

-

The packaging is produced close to the market in which it is sold. It contributes to less traffic and more local jobs. Bonus if the product is also made locally.

-

Magnets are made of different ferromagnetic metals and their strength can vary depending on their composition. They are sometimes used in premium packaging as a method of closure and therefore require consideration for easy sorting of the material if the packaging is intended for recycling.

-

The process of joining two or more flat materials into one. Generally this is done by applying an adhesive to one material and gradually pressing the other onto it until they are joined. Examples are laminating paper and PP film.

-

Plastic particles smaller than five millimetres.

-

Foam made from mushrooms grown on natural fibres such as hemp or flax. The final product is comparable to polystyrene (EPS) in drop and compression tests, but has a longer manufacturing process. The sponges currently require about one week of growth before the final mould is baked and ready for use. This is not a problem when specifying standard parts such as corner bumpers, but can be problematic for custom projects under tight deadlines.

-

Plastic particles smaller than 0.001 millimetres.

-

The official eco-label of the Nordic countries.

-

Standard used mainly in North and Latin America. It includes paper such as American Letter (8.5 x 11 inches or 216 x 279 mm).

-

Hardwood commonly used for the manufacture of shipping pallets.

-

A type of foam that has an open cell structure similar to that of the Eiffel Tower. This allows moisture and gas to pass through.

-

Post consumer recycled - consumer material that has been recycled and made into new consumer goods or packaging. It is important to understand that recycling does not always mean circulation - often consumer materials are recycled in closed systems; such as burning material to produce energy.

-

Polyethylene - one of the most common thermoplastics used worldwide. Applications include plastic bags, packaging films and detergent bottles. PE comes in many varieties to suit specific applications (see HDPE and LDPE).

-

An organisation that works throughout the forest supply chain to promote best practice in forests and ensure that forest-based products are produced to the highest environmental, social and ethical standards.

-

Polyethylene terephthalate - a thermoplastic commonly used for food packaging and water bottles. It is versatile, durable and easily recycled worldwide (rPET). It is also used to make polyester fabric.

-

Polylactic acid - a biothermoplastic commonly used in food packaging and disposable tableware. It is also a standard material in 3D printing.

-

Polypropylene - typically a designer favourite as it is slightly stronger and more heat resistant than PE (polyethylene). It is commonly used for household products such as pens or kitchen utensils, and many types of packaging bottles and films. Another advantage is its ability to be integrated into a hanging system (like the lid of a Tic Tac container). Easily recyclable worldwide and a common food safe material.

-

Polypropylene can be produced as a thin film that is commonly used for labels, plastic packaging and surface coatings.

-

Polystyrene - one of the most common thermoplastics used worldwide. Applications include food containers (yoghurt and sour cream), garden pots and CD covers. PS has good visual clarity, hardness and recyclability.

-

Polyurethane - a thermoset commonly produced as foam (acoustic panels or foam mattresses) but also available as a durable rigid plastic (shopping trolley wheels or surface sealants). Because it is part of the thermoset family, it cannot be transformed by heat and is therefore difficult to recycle.

-

Polyurethane foam - a thermoset foam that is commonly produced as acoustic panels or foam mattresses. It is a lightweight, open cell material that can be molded and is great for protection in a package. Difficult to recycle but can be obtained as an industrially recycled material.

-

Polyvinyl acetate - a thermoplastic adhesive known as white glue, wood glue, school glue, etc.

-

Polyvinyl chloride - thermoplastic used primarily for industrial components and piping. Not common in packaging.

-

Paper made from compressed and drying pulp is a strong sheet of cellulose fibre with a wide range of applications. It is commonly made from wood fibres, but can alternatively be made from bamboo, sugar cane, textiles, etc.

-

Paper is generally made from a mixture of plant fibres that are pressed into flat sheets. Depending on how this pressing is done, the result will be a paper with extremely flat and mixed fibres, or alternatively a paper with a lot of texture. The paper tooth refers to this texture. Cold pressed paper generally provides thicker teeth.

-

A series of small holes punched into the material to aid tearing. Patterns may vary.

-

Durable softwood is sometimes used to make shipping pallets and crates.

-

For example, banana leaves are an early packaging material and are still used in various forms today. They are common in food packaging and can be used fresh or dried and shaped.

-

Plastic is commercially available as blocks in various sizes. They are suitable for manufacturing methods such as CNC machining.

-

Ground plastic pieces - often created by cutting up existing plastic objects to create small plastic shavings that are easily melted and formed into new objects.

-

A commercially available form of plastic that is small in size and designed to be melted for thermal production techniques. The granules look like short hollow tubes.

-

A commercially available form of plastic that is small in size and designed to be melted for thermal production techniques. The pellets are perfectly spherical and are used for more precise machines.

-

Thin plastics are commercially available in rolls. These can be small plastic packages for home use or massive cartridges that fit into production machines.

-

Plastic is commercially available as film in various thicknesses. These are suitable for manufacturing methods such as moulding or laser cutting and vacuum forming.

-

A fibre-based blend that has a porridge-like appearance. It is usually made from water and chemical or vegetable additives, including fibres from wood or alternative sources such as bamboo, sugar cane, textiles, etc. It can be pressed into sheets of paper or moulded into paper-based products such as egg cartons.

-

Recycled cotton has an increasing value in packaging when used as a filling material or thermal insulator. Sourcing can be relatively cheap due to the abundance of cotton resources in the textile industry. The downside, however, is that it requires a protective layer (usually plastic) to prevent wetting when exposed to moisture - perhaps worthwhile when considering an overall reduction in plastic.

-

The packaging is produced with a reduced amount of water. Packaging made from paper and cardboard is often water intensive.

-

The packaging is made from renewable energy sources such as water, wind or sun. It reduces the demand for fossil fuels.

-

Norwegian symbols explaining where and how packaging should be sorted.

-

Metal commonly used in packaging in the form of cans and containers. Provides a long service life. Easily recyclable.

-

The state-of-the-art pulp moulding process achieves smooth surfaces and precise details, for packaging where details really matter.

-

Plastics that soften when heated and harden when cooled. They can be reshaped many times and even melted into liquids for moulding purposes. Most plastics used in packaging are thermoplastics.

-

Plastics that behave like cement - once they harden, it is impossible to heat them up and change their shape. As a result, they cannot be easily recycled. Examples include epoxy and silicone.

-

A pulp moulding process that is cheaper and produces pulp moulds with greater wall thickness (2-10 mm), great for stuffing.

-

The cleaning symbol is present on many packaged items and is a reminder to the customer to handle the packaging appropriately. This does not mean that the item is recyclable.

-

The pulp forming process, a mid-level process that produces thinner molds with higher precision, such as coffee cup carriers.

-

The Universal Recycling Symbol is an internationally recognised symbol used to indicate recyclable materials. The recycling symbol is in the public domain and is not a trademark.

-

PU (polyurethane) foam is often supplied in sheet form and is die-cut during production. As a form of industrial recycling or up-cycling, the offcuts are combined back into large composite boards. Up-cycled PU foam looks like multi-coloured terrazzo as it is often made from many different colours.